Utilizing a Pugmill or Pug Mill and how it can save you time and money as a potter.

1) What is a Pugmill?

A pugmill is a machine in which clay or other materials are mixed and extruded until the material is introduced back into a plastic or homogeneous state with little effort.

2) Types of Pugmills for different purposes.

The topic of pugging clay and its efficiency can be very useful. By this we mean there are several different types of pugmills for different purposes. There are clay mixers, regular standard pugmills and large batch pugmills. Today we will be talking about the combo pugmill/mixer. More specifically a pugmill/mixer with a de-airing chamber or (Vacuum Chamber) to be exact. Below are a few links to various pugmill manufacturers for pottery clay mixers.

Peter Pugger | World Leader in Vacuum Deairing Mixing Pugmills

Buy Pugmills, Puggers & Clay Mixers. Bailey Ceramic Supply (baileypottery.com)

3) Why use a Pugmill?

If you’re an artist, you know that time in the studio is valuable along with controlling costs and energy. Reclaiming clay along with pugging new clay can have many benefits if you are lucky enough to have one of these machines. Let’s start with scraps from the different processes you may be using. Wheel throwing, trimming, and hand building scraps can pile up quickly and start to add cost to both your space and materials when pricing your pieces. Having a steady routine for reclaiming clay can help save on these costs.

Depending on the size of the pugmill and its capacity it can save you time and energy when considering what it takes to wedge. Sure, some may think this is cheating, but think of benefits. Especially if you are a production potter.

1) You set the mixer and walk away to work on something else.

2) Your physical energy will be saved for the wheel.

3) Less muscle stress on your body.

4) Less coning the clay when centering to help deplete the clay from air pockets.

5) If you have old clay that is hard and has been sitting a while you can now utilize it without a lot of work.

6) You can charge your customers less and keep your profit margin when you reduce time with mixing and pugging instead of hand wedging.

7) You can let your customers know you recycle materials, and nothing goes to waste.

4) How does a pugmill work, and should you invest in one?

When clay dries out or loses its plasticity it needs to be reconstituted to an original state to where all the particles can be realigned. If these particles are not in alignment, it can cause serious defects in your pieces, not to mention hard to work with. Once this is accomplished it can be like using new clay out of the bag if processed correctly. Clay that has dried out needs to be what we call “slaked”. The clay needs to grow some bacteria, and it is hard to accomplish this with dry clay. If you are using dry clay, it is recommended that you add some more wet clay or slop to the mix. If all you have is dry clay, then you can break it into small pieces safely and place them in a bucket with just enough water to cover the pieces. They will need to slake for a few days before using and then prepped for the pug mill (we will cover this in another post). For now, let’s assume you have good scraps to work with.

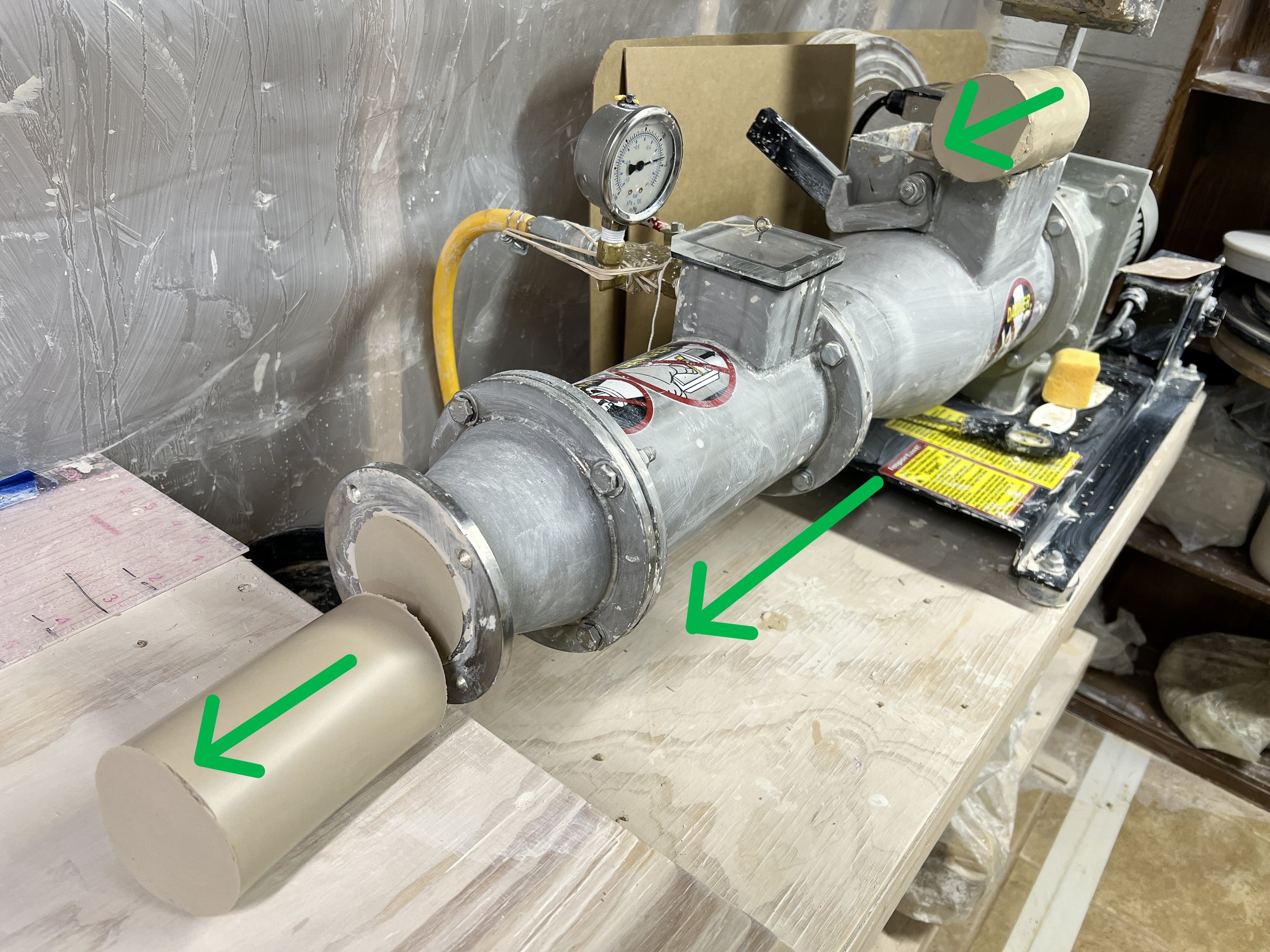

With a pug mill that can mix, pug, and de-air, it’s like having three machines in one. The auger motor drive has both forward (for pugging) and reverse (for mixing). Along with this there is what is called a vacuum chamber that utilizes a separate vacuum pump to help get those pesky pinholes out of your clay. Sometimes the clay may need to be cycled more than once through the pug mill with the vacuum. Wouldn’t you rather save your strength and energy for wheel throwing. Sure, you could sit there and wedge all day before you get to the wheel when your arms are about to fall off. But if you’re like us, we want to get on that wheel as fast as we can. Bottom line as a production potter, YES you should at some point invest in the right one for your application and volume. Generally you may be lucky enough to find a good deal second hand used on trading websites or even FB groups like Pottery Tools & Equipment or Pottery and Ceramic Equipment for Sale. Your life will change once you have one of these in your pottery studio.

5) How Does Reclaiming Work?

Here is how it can work for you. Say you have a pile of semihard and soft clay. You can take a little bit of both and place them into the chamber or hopper of the pug mill together. Closing the chamber, it can then be turned onto the “Mix” setting. As it turns a few times you may be able to add more to help fill the chamber. You will need to let it mix for anywhere from 5 to 15 minutes. Safely check the clay for its plasticity to the point where it does not break apart or seems dry. NOTE: Never stick your hands into the mixing chamber. Use a spoon or other tool. You can then turn on your happy vacuum chamber and switch it to “Pug” mode. The clay may need to be processed through the pug mill more than once. Break a sample piece apart and see if it has pin holes and is back to plastic state for use. If it seems too dry you can add more slop to the chamber and mix some more, or possibly add a little bit of water at a time.

An important note with pugging clay. You may want to take note of which direction the clay is coming out of the pug mill at the end. If you need to process the clay more than once you want to keep the direction of the particles in alignment when pugging. By this we mean keep the front end of the piece you cut off to the front end of the hopper or chamber when putting it back in. If you reverse it, you may end up with s-cracks or other defects in your pieces because the particles will be scattered. Clay has a memory, and this will not work in your favor.

Let’s Review (Summary)

A pug mill can be a very wise investment for production pottery and for those who may not be strong enough to wedge clay. Saving time wedging clay, reclaiming clay, and prepping for your projects will be made easier with one of these awesome machines. It can make reconstituting or the reclaiming process much more productive, saving time and money. Being able to utilize old scraps and greenware that did not turn out can now be used for your next perfect pot. Go forth and reclaim. Below are few videos that may be helpful that we found helpful for us.